A research team has developed the design of materials that improve the process of obtaining hydrogen from water using microwave radiation. The process allows hydrogen to be obtained from renewable electrical energy, thus avoiding CO2 emissions from hydrogen production.

The research focuses on significantly improving the production of green hydrogen through redox cycles, in which the material takes in and releases oxygen from water, stably separating it from oxygen. The developed process allows green hydrogen to be obtained from renewable electrical energy due to the design and use of materials with redox properties that respond to microwave radiation. The basis of the redox chemical cycle is the transfer of electrons between atoms of different elements in the presence of the induced electromagnetic field, which allows the electrification of the process.

Microwaves provide unique advantages in the electrification of a redox process, such as the supply of electrical energy without the need for contacts and the drastic decrease in the temperature of the cycle (from 1300 ºC to 400 ºC), which also reduces the complexity of the process of obtaining H2 and maximizes energy efficiency.

The main novelty of the work is the exhaustive study of the material properties that determine the performance of the process. The bases for material design have been laid to tailor the production of oxygen and hydrogen and adjust the energized state of the material depending on the desired application. In addition, it has been demonstrated that oxygen can be extracted through a highly controlled and fast pulsed process.

"The design of the cavities or chambers where we apply microwaves, as well as the control of the radiation process on these materials, is essential to take advantage of the unique benefits offered by microwave technology. This technology has been established in numerous industrial applications in recent years due to its rapid scalability and high energy efficiency," explains Jose Manuel Catalá, director of the Institute of Information and Communications Technologies Institute at Universitat Politècnica de València.

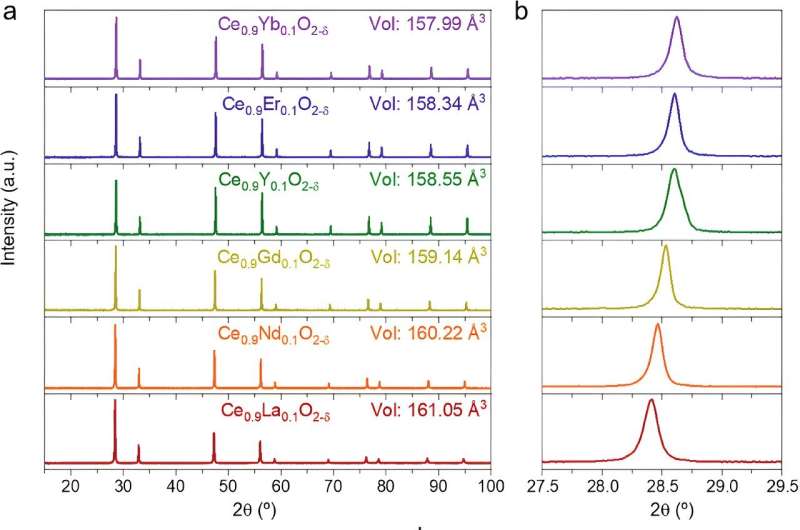

During the research, a detailed study of the influence on hydrogen production of different dopants introduced into the matrix material (cerium oxide) was conducted to adjust the interaction with microwave radiation and the properties of the resulting energized material. "Subsequently, we have studied the hydrogen production capacity of this material and the mechanism that governs the process, which will facilitate the future design of materials," says Manuel Serra.

The study, published in the Advanced Energy Materials journal, has shown that the materials designed and used for hydrogen enhancement are strong and stable.

More information: Aitor Domínguez‐Saldaña et al, Enhanced Hydrogen Production in Microwave‐Driven Water‐Splitting Redox Cycles by Engineering Ceria Properties, Advanced Energy Materials (2024). DOI: 10.1002/aenm.202401443

Citation: Materials improve hydrogen production from water using microwave radiation (2024, July 23) retrieved 23 July 2024 from https://techxplore.com/news/2024-07-materials-hydrogen-production-microwave.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.