Dr. Peter King, a manufacturing researcher at our Clayton site, came across a problem in the lab six years ago. He found that before the team could start any lab work, they had to spend a lot of time programming.

"This was the case with every new project, and it created a time management problem for us," Peter says.

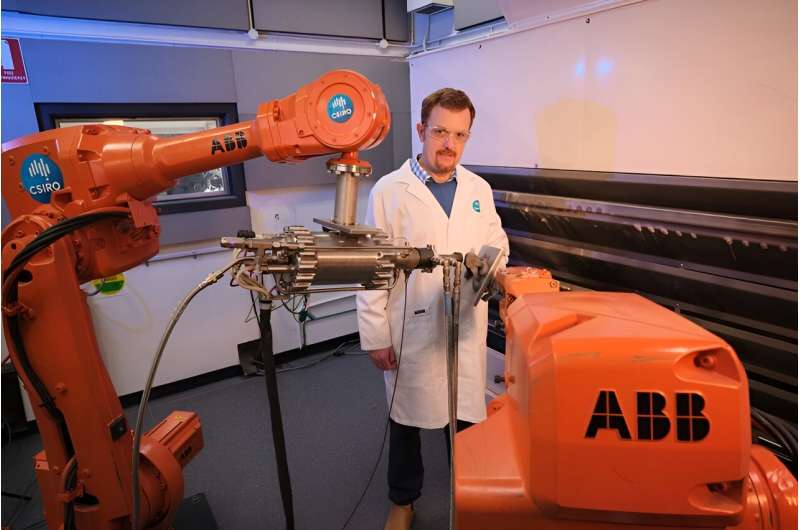

Continuous3D was born. It was initially a strategic project intended to make lab work more efficient. It has now evolved into an entrepreneurial venture, with Peter leading the charge.

"Once we had Continuous3D running in several of our labs, we started to ask if this could be useful to anyone else," he says.

A robot needs to be programmed to do each task. Every time work comes in, the task may be something completely different—especially with repair work. Continuous3D technology enables robots to work in unstructured environments, and do jobs like repair machinery, with software that allows the robot to scan and understand its environment.

"Robots are actually not very smart, they need a lot of programming, a lot of instructing, in order to get them to do what people want them to do," Peter says. "We give the robots brains."

With Continuous3D, the robots are smart enough to do jobs that normally require manual labor. This allows the humans to concentrate on more important tasks, which increases productivity. It also addresses safety concerns, as it leaves the more dangerous or risky repairs to the robots.

While the technology started in our labs, Peter and the team have discovered the problem exists in several different applications and industries. While exploring how to best commercialize their technology, Continuous3D started working with industry to conduct demonstrations and industry trials.

Validating technology to create more valuable research

How did they take the project from our labs to market?

"It started with understanding the market. We needed to find out if other people were experiencing similar problems with robot programming inefficiencies," Peter says.

From there they participated in ON Prime, a program designed to help researchers test their assumptions in the market and validate the need for their solution with customers. Through this program the team spoke with a range of industry contacts and companies, and found their experience was common. They have continued conducting customer conversations as their idea keeps evolving.

"Regardless of what you are working on, it's always useful to investigate how a technology is solving other people's problems," Peter says.

"That should always inform our research… does it make sense from a practical use point of view? Are people going to pick this up? Even if the technology is great, even if it's two times better or 10 times faster, do people really care about it?

"Understanding that is very valuable because it ultimately creates more valuable research."

Citation: Robo-revolution: From lab to market (2024, June 17) retrieved 17 June 2024 from https://techxplore.com/news/2024-06-robo-revolution-lab.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.