The combined thermal degradation of olive pomace and plastic waste by pyrolysis increases the effectiveness of the process and generates new value-added products, such as biofuels, according to a study by the University of Córdoba.

The work is published in the journal Renewable Energy.

The Circular Economy seeks to minimize waste and maximize the use of existing resources. Deriving value from by-products and waste produces economic benefits, while also reducing dependence on fossil fuels and promoting the use of renewable resources. Thus, it is both economically attractive and beneficial for the planet.

Through recovery processes, new lives can be given to single-use plastics, an industry that generates tons of non-degradable waste. By including these plastics in the co-pyrolysis process, it is possible to not only to reduce their environmental impact, but also exploit their energy. In addition, useful bioproducts can be obtained through the thermal transformation of olive pomace, the main byproduct left after the production of olive oil.

This philosophy is part of the latest work of the BIOSAHE group at the University of Córdoba, in collaboration with the Italian University of La Tuscia, in which they have carried out a kinetic and thermodynamic study of different compositions of plastic materials with olive pomace, verifying the effectiveness of this combination.

"Co-pyrolysis is a thermal process that involves the simultaneous degradation of biomass, such as olive pomace, and plastic waste, at high temperatures in the absence of oxygen. This process is important because it makes it possible to convert waste that would otherwise be discarded into valuable products, such as bio-oils, biochar and combustible gases, such as hydrogen.

"In addition, it helps reduce the amount of waste in landfills and reduces greenhouse gas emissions, contributing to more sustainable waste management. The results indicate that the mixture of olive pomaceand plastics generates synergistic effects, since there is a decrease in the activation energy necessary for the process and an improvement in overall efficiency," explained researcher Nélida Sánchez, who co-authored the work with Miguel Carmona, Pilar Dorado, and Sara Pinzi, all members of the BIOSAHE group.

By combining these materials in the co-pyrolysis process, we can not only reduce their environmental impact, but also take advantage of their energy. In this way, providing a joint solution to olive pomace and thermoplastic waste in a 50% mixture has proved to be a much more efficient solution than pyrolysis separately for each, as less energy is needed and fewer polluting gases result from the process.

In addition, this joint treatment could yield products such as bio-oils, biochar (charcoal that improves the properties of soil) and gases that can be used as biofuels, thus both contributing to the production of renewable energy and reducing greenhouse gas emissions too.

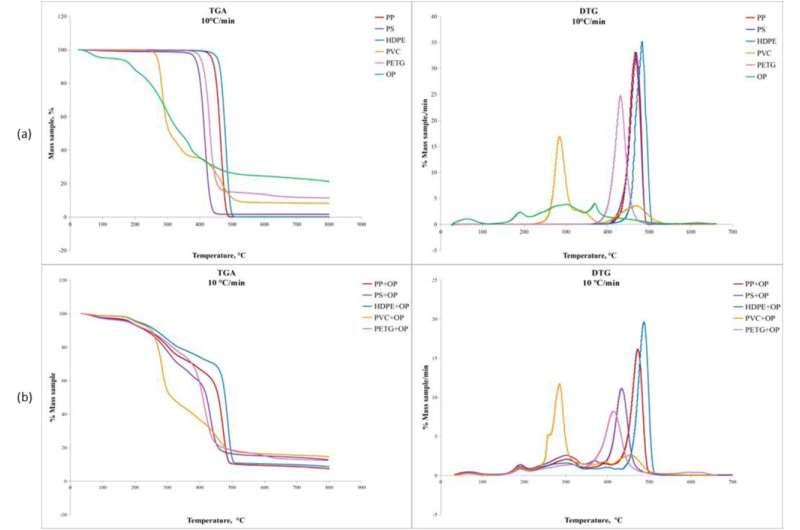

This work, which analyzes the kinetic and thermodynamic behavior of this process, was carried out in an inert atmosphere (without the presence of oxygen), a fundamental aspect to guarantee the process's safety, preventing unwanted oxidation reactions; improve the quality of the products obtained, and facilitate a more precise investigation of the reaction mechanisms involved, minimizing the emission of polluting gases.

In addition, thermodynamic analysis showed that the process is viable and can be optimized for industrial applications. According to Carmona, another of the authors, "We wanted to know all the details of the process so that we could then scale it to an industrial level, improving its energy efficiency and optimizing the conditions of the process based on the proportion and composition of the products we want to obtain."

Having all the possible knowledge at the laboratory scale is key to optimizing these complex thermal degradation processes, resulting in an efficient process at the industrial level without generating the pollution associated with combustion, and obtaining other quality products to continue feeding the Circular Economy circuit.

Evaluating the composition of the resulting products and determining the optimal mixture of olive pomace and plastic waste to obtain bio-oils and other useful products of better quality, depending on the applicability sought, are the next steps that this research group will take to extend the life of these products and reduce their environmental impact.

More information: N. Sánchez-Ávila et al, Kinetic and thermodynamic behavior of co-pyrolysis of olive pomace and thermoplastic waste via thermogravimetric analysis, Renewable Energy (2024). DOI: 10.1016/j.renene.2024.120880

Citation: Copyrolysis of olive pomace and plastics reduces energy and polluting emissions in bioenergy production (2024, July 30) retrieved 30 July 2024 from https://techxplore.com/news/2024-07-copyrolysis-olive-pomace-plastics-energy.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.