Polishing the future: Advanced magnetorheological polishing techniques for ultra-precision machining

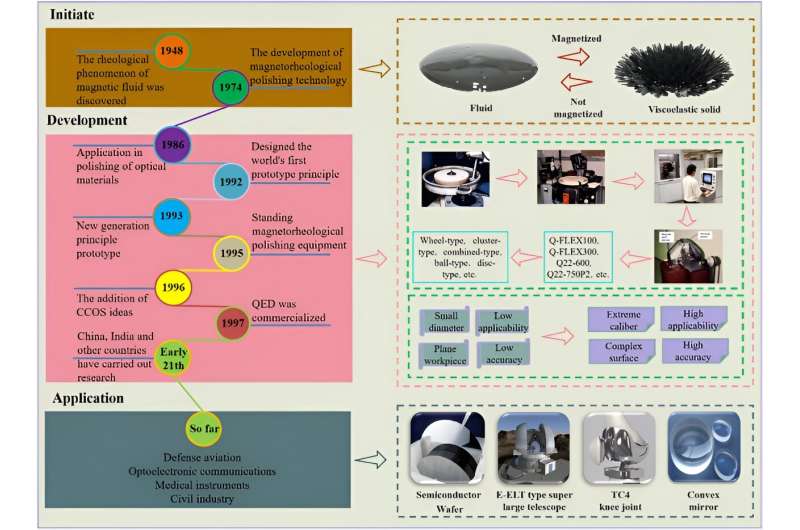

Precision is paramount in high-stakes industries such as aerospace, electronics, and medical devices, where traditional polishing techniques fall short. The rise of magnetorheological (MR) polishing technology offers a beacon of efficiency and quality, crucial for overcoming the limitations of conventional methods. The quest for enhanced processing precision and efficiency has never been more pertinent, spurring the necessity for intensive research into MR polishing advancements.

In a collaborative effort, Changchun University of Technology and Jilin University have achieved a significant milestone in MR polishing. Their comprehensive review, published on May 16, 2024, in the Advances in Manufacturing journal, delves into the latest material innovations and process refinements in MR polishing technology.

The review paper provides a comprehensive analysis of various magnetorheological polishing technologies, including wheel-type, cluster-type, ball-type, and disk-type methods. Each method is assessed based on processing accuracy, efficiency, and application range.

The authors highlight the innovative curvature-adaptive magnetorheological polishing technology, which features a circulatory system for high-efficiency, high-quality polishing. This method stands out for its ability to maintain consistent polishing quality across different surfaces.

The review also delves into the development of advanced polishing materials and magnetorheological fluids, which are crucial for improving the overall polishing process. Theoretical research, equipment advancements, and practical applications are thoroughly explored, demonstrating the technology's potential to revolutionize surface finishing in ultra-precision machining.

The analysis underscores the importance of these advancements in meeting the high demands of modern manufacturing industries, paving the way for future innovations and applications.

Dr. Jie-Qiong Lin, a leading figure in precision machining from Changchun University of Technology, emphasizes, "The strides made in MR polishing technology are not incremental but revolutionary, offering unprecedented possibilities for high-precision applications across various industries."

The research bears profound implications for the future of manufacturing, particularly in the production of intricate, high-precision components. MR polishing is destined to bolster the quality and reliability of products in aerospace and electronics, among other fields.

Additionally, the technology's alignment with eco-friendly manufacturing practices points toward a sustainable evolution in the industry. As MR polishing technology continues to advance, it stands as a cornerstone for the next generation of precision machining.

More information: Ming-Ming Lu et al, Research progress of magnetorheological polishing technology: a review, Advances in Manufacturing (2024). DOI: 10.1007/s40436-024-00490-4

Citation: Polishing the future: Advanced magnetorheological polishing techniques for ultra-precision machining (2024, June 3) retrieved 3 June 2024 from https://techxplore.com/news/2024-06-future-advanced-magnetorheological-techniques-ultra.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.