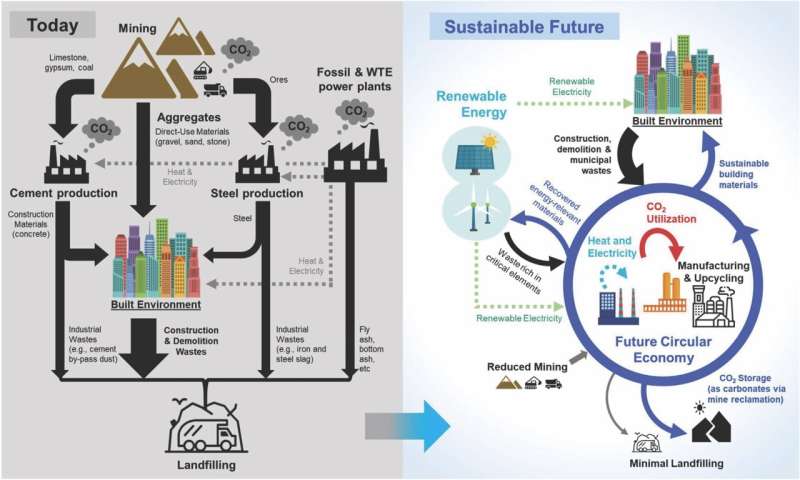

The built environment—infrastructure for buildings and transportation—currently produces a large portion of global carbon dioxide emissions, but new technologies have the potential to transform the built environment from a carbon source to a carbon sink.

Researchers released recommendations on how the construction sector can incorporate new materials and processes to help reduce or capture and reuse CO2 emissions in a recent perspectives piece published in Frontiers in Energy Research.

As humans continue to emit CO2 into the atmosphere, warming the planet and causing climate change, the U.S. and many other countries around the world are making commitments to reduce their carbon footprint.

Buildings and the construction sector account for about 39% of energy-related global CO2 emissions annually, positioning the built environment as a major focus of decarbonization efforts. For this reason, the U.S. Federal Sustainability Plan set forth an ambitious goal to achieve net-zero emissions buildings by 2045.

"Climatologically, we are running out of time. We can no longer continue to build the way we have always done," said Volker Sick, Director of the Global CO2 Initiative and the DTE Energy Professor of Advanced Energy Research at the University of Michigan and contributing author on the study.

The multidisciplinary team emphasized that we need to think carefully about construction now as infrastructure lifespans are often 50 to 100 years long.

"Any opportunities we miss now, we miss for a century," said Sick.

Currently, the aging built environment in the U.S. is far below sustainability standards, earning a C- on the American Society of Civil Engineers' infrastructure report card in 2021. Replacing deteriorating infrastructure offers an opportunity to think strategically about developing the built environment with climate change mitigation in mind.

"Our living and working spaces could fundamentally shift the battle against climate change, playing a pivotal role for generations to come. Embracing these innovations isn't just technologically interesting, it's imperative for a sustainable future," said Ah-Hyung "Alissa" Park, the Ronald and Valerie Sugar Dean of the UCLA Samueli School of Engineering and corresponding author of the study.

Adapting to the changing climate and adhering to new policies will require collaboration among industry professionals involved in the entire built environment life cycle—from mining raw materials to demolition.

There is no single solution to achieving zero-carbon buildings or even reducing built environment CO2 emissions. The research team highlights new technologies to reduce or capture CO2 emissions during four stages of a structure's life cycle—processing materials, construction, building use and demolition.

Processing materials

Global urbanization trends create a massive demand for concrete, but conventional materials like Ordinary Portland Cement—a concrete component—have a high carbon intensity with about 0.6 tons of CO2 emitted for every ton of cement produced.

Cement supplements like fly ash—a waste product from coal power plants—are already used to partially replace cement, which reduces the need to mine raw materials. However, to meet the large demand for concrete, an alternative cement must be abundantly available worldwide.

For this reason, engineers are developing magnesium-based cements, rather than the traditional calcium-based versions, as magnesium is abundantly available in the Earth's crust and seawater. Raw magnesium materials can be harvested emission-free through electrochemical pathways, and magnesium-based cements can even be captured from wastewater sludge.

Steel is another high demand material with a large carbon footprint, producing 1.91 tons of CO2 per ton of crude steel cast. Biofibers, CO2-based polymer fibers, carbon fibers and carbon nanotubes have been tested as steel alternatives, aiming to reduce CO2 emissions while improving corrosion resistance. Carbon nanotubes can be made from seaweed contaminated with plastic, offering an additional benefit of upcycling waste materials.

Despite the advancements in steel replacements, in some cases, steel's great strength and ductility make it irreplaceable. Instead, changes to the steel manufacturing process can help reduce CO2 emissions (e.g., switching fuels from coke and coal to gas and biomass, replacing furnaces with efficient electric arc furnaces and incorporating hydrogen into steelmaking).

Construction

With new materials come new construction techniques. Additive manufacturing, known commonly as 3D printing, accompanied by lean manufacturing to minimize waste, can help develop future buildings and infrastructure incorporating the new materials mentioned above.

"Concrete 3D printing presents an unparalleled opportunity to advance a new construction paradigm, harnessing the integration of novel materials like low CO2 cement, CO2 sequestered fillers and unconventional bio-based binders.

"These materials not only align with the performance demands of 3D printing but also introduce possibilities beyond the constraints of conventional construction methods," said Mahmoud Taha, a Distinguished Professor and Regents' Lecturer at the Gerald May Department of Civil, Construction & Environmental Engineering at the University of New Mexico and contributing author on the study.

"The primary hurdle lies in the substantial investment required to catalyze this breakthrough within an inherently conservative industry," added Taha.

Construction techniques can also actively reduce CO2 emissions through using CO2 as a feedstock or capturing it. CO2 use, like curing concrete in a CO2 environment, reduces the carbon footprint of materials while producing a stronger material.

CO2 capture from construction waste directly converts CO2 into solid carbonates in a process known as carbon mineralization. These solid carbonates can then be recirculated into the supply chain as building materials or stored for deep CO2 sequestration.

"Carbon dioxide capture and use offers us the opportunity to help stabilize the climate, and to add critically needed jobs especially in underserved regions of the world. These are all urgent needs that require swift and large-scale action," said Sick.

Building use

Once constructed, the built environment continues to consume energy to accommodate occupants or activities. Buildings in the U.S. account for three-fourths of electricity consumption, offering an opportunity to implement impactful energy use changes.

Improvements to sensing and computational capabilities can increase a building's demand flexibility, or ability to manage its energy demand according to electrical grid conditions, local climate or user needs.

Multi-functional materials can also improve building sustainability, like solar cells in roofing and windows to generate energy on-site or phase-changing materials as insulation to improve heat modulation.

Demolition

Better demolition practices can help develop well-separated waste streams to effectively recover materials, like rare-earth elements for energy use or industrial alkaline wastes (e.g., iron and steel slag, red mud, waste-to-energy ashes, mine tailings or waste concrete) for carbon capture through mineralization.

Upcycling waste aggregates could optimistically recapture up to six gigatons of CO2 per year by 2050. Overall, creating circularity for construction materials will develop a sustainable future economy.

To achieve the shift from a carbon-emitting to a carbon-storing industry, technologies must mature—growing supply chains and manufacturing bases—while policy changes support economic viability.

More information: Ah-Hyung Alissa Park et al, Challenges and opportunities for the built environment in a carbon-constrained world for the next 100 years and beyond, Frontiers in Energy Research (2024). DOI: 10.3389/fenrg.2024.1388516

Citation: Capture and reuse opportunities for CO₂ in the construction sector in the next 100 years (2024, May 20) retrieved 20 May 2024 from https://techxplore.com/news/2024-05-capture-reuse-opportunities-sector-years.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.