Researchers have developed a new manufacturing technology that enables the production of high-quality oxide films and effective patterning at low temperatures and manufactured non-volatile resistive random access memory. It is expected to be used in next-generation computing systems by overcoming the shortcomings of existing manufacturing technologies and developing memories with excellent durability.

Recently, the development of data-intensive computing systems, such as artificial intelligence, big data, and the Internet of Things (IoT) devices, increased the demand for new next-generation non-volatile memory that offers excellent durability, greater operating speed, and low power consumption. The resistive random access memory, a type of memory, changes memory information through current.

The solution process technology, which attracts attention as a method of developing resistive random access memory, enables cost-efficient manufacturing in a large area. Nonetheless, it has the disadvantage of operating only at high temperatures, and it is challenging to form a uniform pattern.

The research team was led by Professor Hyuk-jun Kwon of the Department of Electronic Engineering and Computer Science, and the study's first author is Bong-ho Jang.

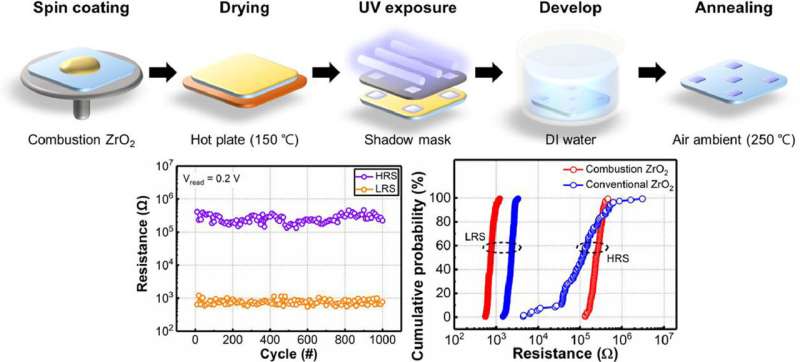

Professor Kwon's team has combined the combustion synthesis technology with the solution process to overcome these shortcomings. The combustion synthesis technology utilizes exothermic reactions to synthesize materials using the heat generated during combustion. For this reason, this technology helps address the shortcomings of the solution process, as it is unnecessary to provide high temperatures from the outside.

Professor Kwon's team applied this technology to the precursors of the solution process and obtained high-quality zirconium oxide (ZrO2) film and photopatterning effect through photochemical reaction with ultraviolet rays, even at lower temperatures.

Furthermore, the research team produced a resistive random access memory using the technology. The manufactured resistive random access memory has significant durability, enduring more than 1,000 cycles and retaining data for more than 100,000 seconds in a high-temperature environment.

Previously, Professor Kwon's research team had applied the combustion synthesis technology to produce SnO2 thin-film transistors at low temperatures. This study expanded the technology's application scope by overcoming the limitations of the existing solution process technology and developing a novel type of resistive random access memory.

Professor Kwon at the Electrical Engineering and Computer Science Department said, "This is the result of significantly improving the problems of existing solution process technology. It is also expected to contribute to intensive next-generation computing systems and mass production of solution process-based electronic devices."

The study is published in the Journal of Materials Science & Technology.

More information: Bongho Jang et al, Stable switching behavior of low-temperature ZrO2 RRAM devices realized by combustion synthesis-assisted photopatterning, Journal of Materials Science & Technology (2024). DOI: 10.1016/j.jmst.2023.12.016

Provided by DGIST (Daegu Gyeongbuk Institute of Science and Technology)

Citation: Research team develops next-generation semiconductor memory that operates in extreme environments (2024, March 29) retrieved 29 March 2024 from https://techxplore.com/news/2024-03-team-generation-semiconductor-memory-extreme.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.