Japanese metal materials maker Proterial has developed a way to make a new alloy for electric vehicle motors that it says can reduce power consumption by up to 5%, allowing for smaller and faster motors.

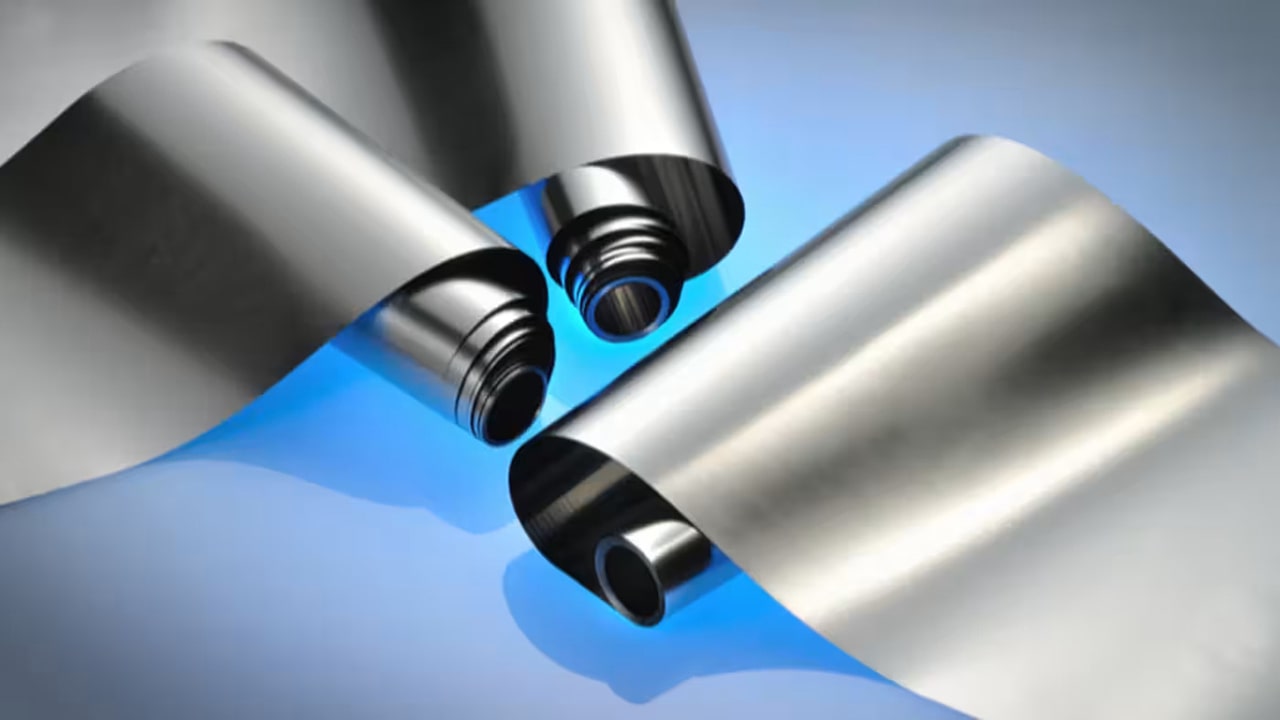

The company, formerly known as Hitachi Metals, has succeeded in processing the alloy into material for EV motor cores.

The amorphous alloy reduces energy loss by 90% or more compared with the non-oriented electrical steel sheet typically used in motors.

Proterial aims to start mass production as soon as 2025.

The alloy presented challenges for Proterial. It is about five times stronger than electrical steel sheets, and so shortens the life span of the tools used to work it. The alloy is also thinner and thus more difficult to work with.

Proterial overcame these hurdles with technology it had used to make transformer cores.

The company will seek to combine this technology with its ferrite magnets to improve the performance of high-speed motors.

These magnets use much less of the heavy rare-earth elements found in neodymium magnets now widely used in EV motors, cutting out terbium and dysprosium. The global supply of heavy rare earths relies heavily on China, which has tightened export restrictions on the metals.

This article first appeared on Nikkei Asia. It has been republished here as part of 36Kr’s ongoing partnership with Nikkei.