A new study led by NIMS researchers reveals that in solid electrolytes, a silicon anode composed only of commercial silicon nanoparticles prepared by spray deposition exhibits excellent electrode performance, which has previously been observed only for film electrodes prepared by evaporation processes. The method is a cost-effective, atmospheric technique, and his new result therefore suggests that a low-cost and large-scale production of high-capacity anodes for use in all-solid-state lithium batteries is possible.

Silicon has a theoretical capacity of ~4,200 mAh/g, which is approximately 11 times higher than that of the graphite commonly used as the anode-active material in commercial Li-ion batteries. Replacing the traditional graphite by silicon can significantly extend the driving range per charge of electric vehicles. However, its huge volume change (~300 percent) during lithiation and delithiation—charge and discharge—hinders its practical application in the batteries.

In conventional liquid electrolytes, the use of polymeric binders is necessary to hold the active material particles in the electrode together and maintain their adhesion to the surface of metal current collectors. The repeated huge volume change of silicon causes the particle isolation, which leads to losing the active material and a resulting continuous capacity loss. In solid-state cells, the active material is placed between two solid components, a solid electrolyte separator layer and metal current collector. In fact, as reported previously by the team of NIMS researchers, the sputter-deposited pure silicon films delivering practical areal capacities exceeding 2.2 mAh/cm2, exhibit excellent cycling stability and high-rate discharge capabilities in solid electrolytes. Nonetheless, cost-effective and industrially scalable synthesis of the anode for all-solid-state lithium batteries remains a great challenge.

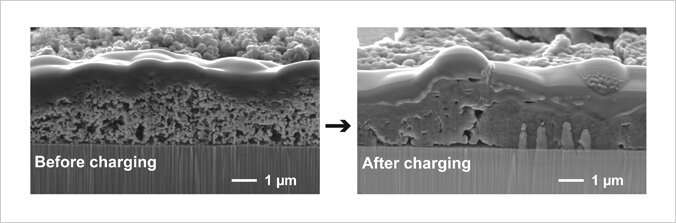

The team of NIMS researchers has taken another synthesis approach toward high-performance anodes for all-solid-state lithium batteries with commercial silicon nanoparticles. They found a unique phenomenon with the nanoparticles in the solid-state cell: Upon lithiation, they undergo volume expansion, structural compaction, and appreciable coalescence in the confined space between the solid electrolyte separator layer and metal current collector to form a continuous film, similar to that prepared by the evaporation process. The anode composed of nanoparticles prepared by spray deposition therefore exhibits excellent electrode performance, which has previously been observed only for sputter-deposited film electrodes. The spray deposition method is a cost-effective, atmospheric technique that can be used for large-scale production. Hence, the findings will pave the way for low-cost and large-scale production of high-capacity anodes for use in all-solid-state lithium batteries.

Continuing efforts by the NIMS researchers to improve the cyclability in the anode are in progress to meet the requirements of electric vehicles .

More information: Narumi Ohta et al, Anode Properties of Si Nanoparticles in All-Solid-State Li Batteries, ACS Applied Energy Materials (2019). DOI: 10.1021/acsaem.9b01517

Citation: High-performance anode for all-solid-state lithium batteries is made of silicon nanoparticles (2019, December 24) retrieved 24 December 2019 from https://techxplore.com/news/2019-12-high-performance-anode-all-solid-state-lithium-batteries.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.