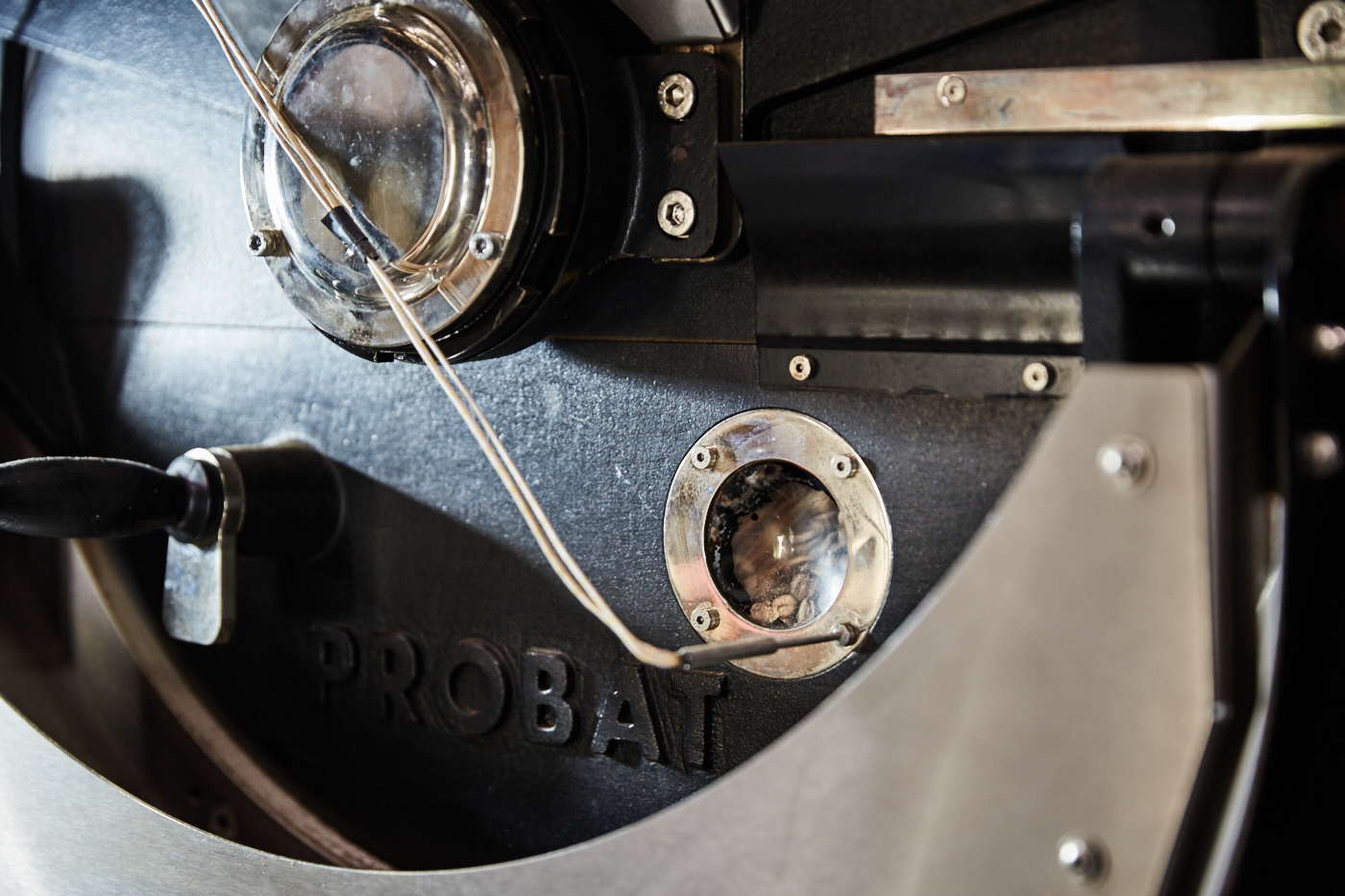

The vast majority of machines I’ve worked on in my consulting career have needed what I call “tuning.” For example, just this past month, a client with a new Probat had far less airflow than he needed, due to his chimney configuration. Two experienced clients were operating with less than half of their respective machines’ optimal gas pressures. Several clients were operating machines with suboptimal drum RPMs or airflow levels. One client had both inadequate gas pressure and inadequate airflow, caused by an air leak at the loading funnel. Several roasters were using excessive software smoothing or slow thermocouples.

Proper gas pressure, drum RPM, airflow level, probe size and location, and software settings are all necessary before one can roast great coffee with impressive consistency. My experience implies that most roasters reading this post likely have tuning problems of which they are not aware. All of the issues below can be remedied quickly or cheaply. Fixing any of them will provide an excellent return on the invested time or money.

Gas Pressure

Every gas burner is designed to work safely and efficiently in some range of gas pressures. For example, your machine’s manufacturer may recommend a range of 3–5 kpa (12–20 inches of water column). The recommended range should be listed on a badge on the side of your roaster or on the manufacturer’s website. What almost no one tells roasters is that pressure at the top of the recommended range offers a lot more power and efficiency than pressure at the bottom of the range. Suboptimal gas pressure forces many roasters to roast smaller or slower batches. I’ve seen increases in gas pressure lead to 50% increases kg per hour of roasted coffee.

Drum RPM

Even if your machine is brand new and the manufacturer installed it for you, check its drum RPM. A few major manufacturers deliver machines of a given model with widely varying RPMs (often a difference of 20 RPM machine to machine). Some whom I’ve asked to fix it for my client have claimed “it doesn’t matter” (one of those same manufacturers has told me that ROR crashes don’t matter, so be careful where you get your roasting advice!) Please count your drum RPM over the course of one minute. If your machine’s RPM are either too high or too low, it will cause more conductive heat damage and harsher coffee. Very low RPM can also contribute to ROR crashes.

My RPM recommendations are in the chart below. If you have a 12kg roaster with, say, 35 RPM (a frequent problem from one manufacturer), you will not be able to avoid ROR crashes and excessive conductive heat transfer. You may be satisfied with roasts from a low-RPM machine, but the coffee will be noticeably better when you adjust the RPM to the proper range.

Airflow

There are many causes of improper airflow levels in roasting: air leaks, such as loading hoppers that don’t seal well, fans spinning in the wrong direction (more common than you would think), chimneys that are too tall or have too many 90-degree angles, or simply roasters adjusting fans and dampers improperly. If your roasting-exhaust and cooling-air chimneys merge before passing through the roof it may cause back pressure in the roasting drum and shifts in roasting airflow depending on whether the cooling fan is on.

If your RORs decline with a relatively constant slope, your ET curve should stop rising somewhere just before or around the beginning of first crack (there are too many factors to be more specific here). If your ET peaks more than two minutes before first crack begins, you probably have too much airflow. If your ET curve rises all the way through the end of a roast, you are probably using too little airflow. And of course, if lots of smoke or chaff pours out of the drum when you drop a light or medium roast, the airflow is probably set too low.

Probes and Software

Quality data collection and presentation are essential to quality, consistent roasting. If the turning points of your roasts are routinely later than 1:30, your probe is probably too slow. If your RORs look very noisy when viewed in the 15-second averaging interval in Cropster RI3 (or the 15s delta span in Artisan), you may have excessive noise in your system. (I covered this issue more thoroughly in my July 4, 2019 post.) If your RORs are smooth, rather than jagged, curves, your smoothing settings are too generous.

Please don’t assume that if you like the way your coffee tastes or your machine is new that it doesn’t need tuning. Few of the roasters I’ve worked with whose machines needed tuning knew there was a problem, but all were happier with their roasts after we tuned their machines.