If realized using solar energy or other renewable energy, water splitting could be a promising way of sustainably producing hydrogen (H2) on a large-scale. Most photoelectrochemical water splitting systems proposed so far, however, have been found to be either inefficient, unstable, or difficult to implement on a large-scale.

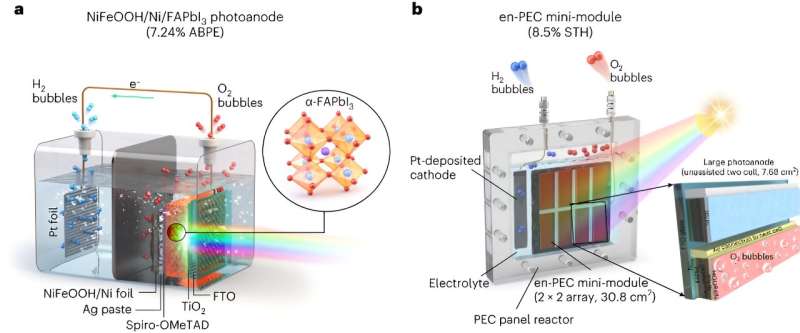

Researchers at Ulsan National Institute of Science and Technology (UNIST) recently set out to develop a scalable and efficient photoelectrochemical (PEC) system to produce green hydrogen. Their proposed system, outlined in Nature Energy, is based on an innovative formamidinium lead triiodide (FAPbI3) perovskite-based photoanode, encapsulated by an Ni foil/NiFeOOH electrocatalyst.

"Our group has thoroughly studied the challenges associated with practical solar hydrogen production," Jae Sung Lee, Professor of Energy & Chemical Engineering at UNIST and co-author of the paper, told Tech Xplore. "As summarized in our most recent review paper, minimum 10% of solar-to-hydrogen (STH) efficiency is required to develop viable practical PEC system, for which selecting an efficient material is the first criteria."

So far, most attempts at realizing photoelectrochemical hydrogen production employed intrinsically stable metal oxides as the photoelectrode materials of PEC cells. These systems, however, have yielded efficiencies far below those necessary for their practical application.

Some researchers have thus been exploring the potential of photoelectrodes based on photovoltaic (PV) grade materials, such as silicon, perovskites, chalcogenides and III-V material classes. While these materials are known for their remarkable efficiencies, they can sometimes be expensive and unstable, especially if placed in water, as they would be if introduced in PEC water splitting cells.

"Unlike other PV grade materials, metal-halide perovskites (MHP) have unique characteristics of high efficiency but low cost and could become an alternative photoelectrode material if their stability issue is properly addressed," Lee said. "The MHP materials have excellent optoelectronic properties and tunable bandgap which are desired to provide necessary photocurrent and photovoltage to split water and produce oxygen and hydrogen in a single PEC cell."

To devise effective photoelectrodes based on MHPs, the researchers first had to tackle a crucial challenge, namely that of maintaining their stability in humid conditions and under UV light. To achieve this, they tried to stabilize them using metal-encapsulation or metal-protection techniques and by adopting the UV-stable FAPbI3 perovskite.

"Another challenge for practical applications is the scalability, or in other words, to maintain the high efficiency of laboratory cells (which are < 1 cm2) in practical large-scale implementations (1 m2)," Lee said. "For our study, we selected the most advanced MHP material in efficiency and stability (FAPbI3) and encapsulated it with a thick nickel foil (30 mm) deposited with an NiFeOOH catalyst to protect MHP in water and promote oxygen evolution reaction for water splitting,"

The researchers firstly created a small-scale version of their proposed system, based on a photoelectrode below 1cm2 in size. In initial tests, this laboratory-scale system achieved a 9.89% STH efficiency and a long-term stability.

More information: Dharmesh Hansora et al, All-perovskite-based unassisted photoelectrochemical water splitting system for efficient, stable and scalable solar hydrogen production, Nature Energy (2024). DOI: 10.1038/s41560-023-01438-x

© 2024 Science X Network

Citation: A scalable photoelectrochemical system for green hydrogen production (2024, February 10) retrieved 10 February 2024 from https://techxplore.com/news/2024-02-scalable-photoelectrochemical-green-hydrogen-production.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.