A team of researchers, affiliated with UNIST has made a significant breakthrough in developing an eco-friendly dry electrode manufacturing process for lithium-ion batteries (LIBs). The new process, which does not require the use of harmful solvents, enhances battery performance while promoting sustainability.

The findings of this research have been published in the July 2024 issue of Chemical Engineering Journal.

Led by Professor Kyeong-Min Jeong in the School of Energy and Chemical Engineering at UNIST, the research team has introduced a novel solvent-free dry electrode process using polytetrafluoroethylene (PTFE) as a binder. This innovative approach addresses the challenges associated with traditional wet-electrode manufacturing methods, which often result in non-uniform distribution of binders and conductive materials, leading to performance degradation.

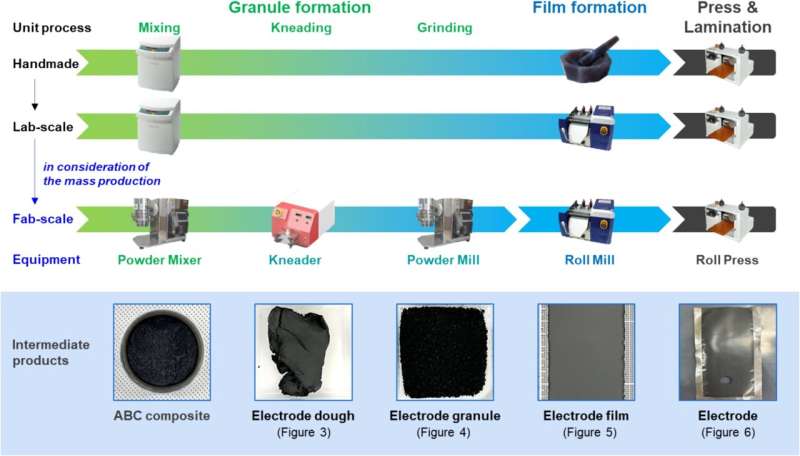

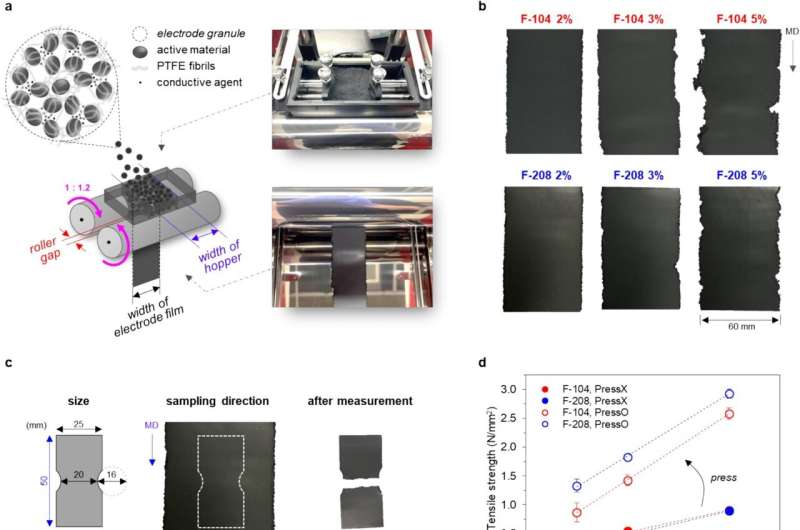

The dry electrode process is divided into four stages: granule formation, film formation, rolling, and lamination. The team optimized the process conditions by evaluating the physical, electrical, and electrochemical properties of semi-finished products at each stage. The results show that a high-extrusion-ratio PTFE binder can produce an electrode film with high strength even with low energy consumption, leading to improved microstructure and power characteristics.

In LIBs, binders play a crucial role in connecting active materials and electrons. The study revealed that the type and content of PTFE binders significantly impact the output characteristics of dry electrodes. The researchers identified an optimal formulation of NCM811/PTFE/carbon black (CB)/carbon nanotube (CNT) = 96/2.0/1.8/0.2, which demonstrated exceptional discharge rate capability of 80% at a 0.5 C-rate (5 mA/cm2) under demanding conditions.

"This breakthrough will contribute to commercialization by providing a scalable and practical solution for mass production," emphasized Professor Jeong. "We believe that our study will pave the way for environmentally friendly and efficient electrode manufacturing for future energy storage applications."

The Korea Institute of Energy Research (KIER) and Hanwha Co., Ltd. have also partnered with UNIST to develop dry electrode-specific manufacturing equipment and demonstrate its commercial viability from the second half of 2024.

The team is planning to further improve the output characteristics of thick electrodes by exploring various materials through follow-up research. With this innovative technology, electric vehicles and electronic devices are expected to become more sustainable in the future.

More information: Hyeseong Oh et al, Development of a feasible and scalable manufacturing method for PTFE-based solvent-free lithium-ion battery electrodes, Chemical Engineering Journal (2024). DOI: 10.1016/j.cej.2024.151957

Citation: Study unveils solvent-free dry electrodes that boost lithium-ion battery performance (2024, July 19) retrieved 19 July 2024 from https://techxplore.com/news/2024-07-unveils-solvent-free-dry-electrodes.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.