On a chilly December evening in eastern Idaho, a semi-tractor trailer truck pulls off the desert highway and up to the gate at the Department of Energy's Materials and Fuels Complex.

The truck and the small, gray shipping container that sits on its trailer appear unremarkable. But the shipping container is sturdier than most, with extra-thick metal, a heavy door and a lid that lifts off the top. There's also a Department of Transportation placard on its side that reads "radioactive."

The truck pulls up to the gate, and Idaho National Laboratory (INL) employees embark on a flurry of paperwork. After some time, the truck pulls through the gate and into a narrow bay attached to the Hot Fuel Examination Facility (HFEF).

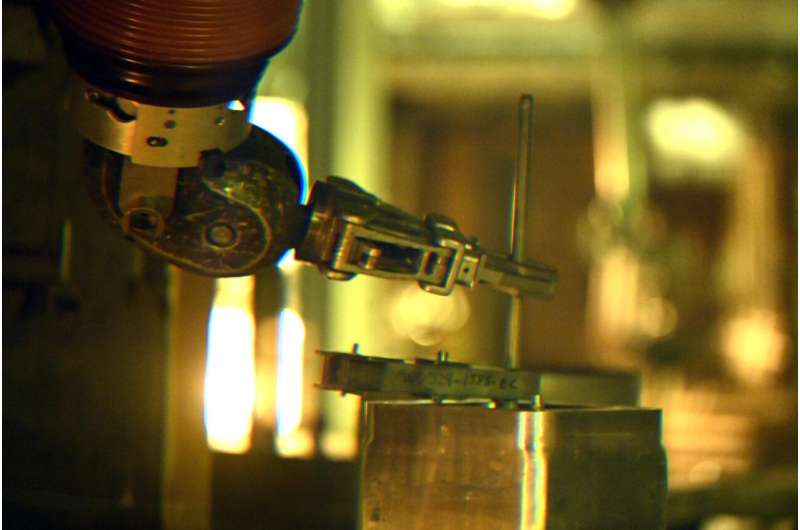

On the roof of the bay, thick metal rails, painted yellow, serve the cranes that remove the shipping container's precious cargo: next-generation nuclear fuel rods that could eventually power the U.S. reactor fleet. The fuel rod technology could save electricity rate payers millions of dollars per year while increasing a nuclear power plant's resilience under potential accident conditions.

But first, INL researchers must subject the fuel rods to several years' worth of examinations and experiments to prove their performance and safety.

Powering the current fleet

Experts say maintaining the current fleet of nuclear reactors in the U.S. is essential to limiting the major impacts of climate change and meeting net-zero emissions goals by 2050.

That's because the 93 nuclear reactors currently operating around the country provide roughly 50% of the nation's carbon-free electricity.

To keep today's reactors operating safely and efficiently—and to prepare for tomorrow's advanced reactors—researchers from industry, universities and national laboratories have developed new nuclear fuels that last longer and are more resistant to accidents.

The Nuclear Regulatory Commission (NRC) requires a rigorous qualification process to make sure these fuels perform as designed. That process includes subjecting prototype fuel rods to years of real-world operating conditions in test reactors and commercial nuclear power plants. Afterwards, researchers conduct experiments and analyses on these samples to thoroughly understand the prototype's performance characteristics.

Now, for the first time in two decades, INL has received a shipment of used next-generation fuel from a nuclear power plant for post-irradiation tests and examination. In December, INL received 25 prototype fuel rods irradiated in the reactor core of a commercial nuclear plant.

The fuel rods were developed and manufactured by Westinghouse Electric Company with technical assistance from several national laboratories, including INL.

Each fuel rod is 12 feet long and the shipment includes about 100 pounds of heavy metal, mostly uranium.

"It's exciting for INL to be open for business again to collect this kind of information," said Josh Jarrell, an INL researcher who serves as the Department of Energy (DOE) senior technical advisor for nuclear fuels. "Bringing this material to INL will help move the nuclear industry forward and demonstrate that INL can be a partner. Similar shipments and data collection in the future will ensure our current reactor fleet is using the most advanced and economical fuels that they can."

Citation: Commercial shipment marks big step for safer, more efficient nuclear fuels (2024, February 23) retrieved 23 February 2024 from https://techxplore.com/news/2024-02-commercial-shipment-big-safer-efficient.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no part may be reproduced without the written permission. The content is provided for information purposes only.